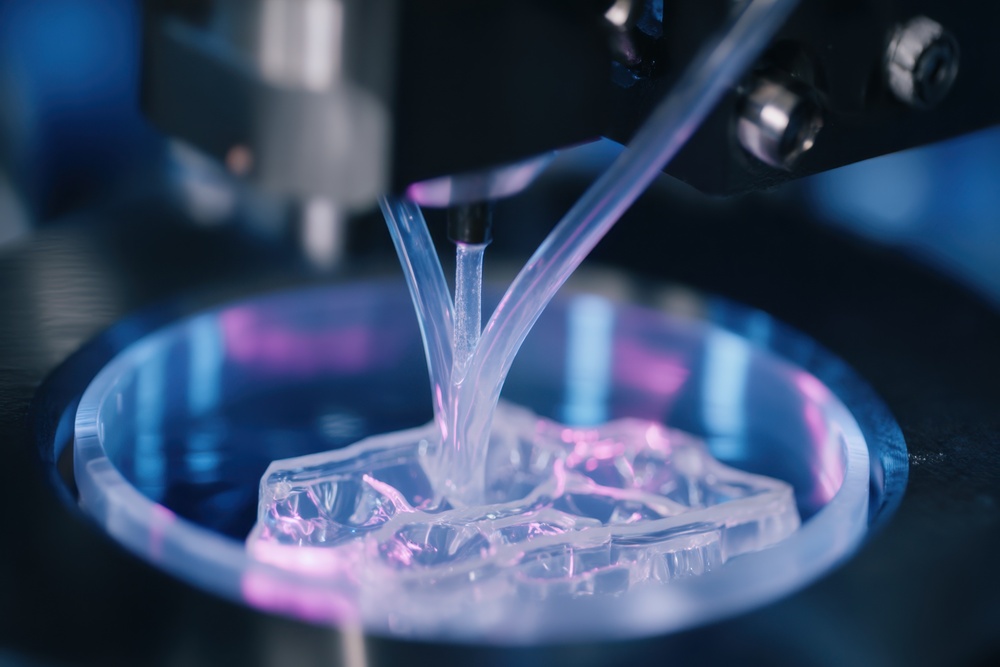

Programmable wax loss microcasting setup pouring molten wax into fine molds, capturing intricate details for high quality jewelry and industrial components in a modern lab

Many individuals associate wax with giving cars a glossy finish or assisting surfers in riding waves. In the corporate sector, wax has evolved into an advanced material that addresses issues in many industries. Contemporary wax technology has advanced significantly past the basic paraffin that your grandmother used for preserving jars.

Beyond Your Grandfather’s Candle Wax

Conventional waxes originated from bees, vegetation, or the refining of crude oil. They functioned well for simple applications but faced significant restrictions. They melted at unsuitable temperatures, deteriorated under stress, and could not meet the requirements of contemporary production.

Today’s wax technology functions on an entirely new level. Researchers have created synthetic options that exceed natural waxes in nearly all aspects. These contemporary materials endure extreme temperatures, withstand chemicals, and offer reliable performance in difficult situations. The change has been remarkable. What used to be a basic commodity has turned into a precisely designed answer for intricate industrial problems.

Where Modern Wax Makes a Difference

The number of common items that depend on sophisticated wax technology might take you aback. That sleek layer on your morning medications? Wax enables that to happen. The release agent that stops your frozen foods from clumping during processing? Also, wax.

Automobile producers utilize specific waxes within their painting systems and protective finishes. Food processors depend on wax technology for a range of tasks, including candy making and packaging uses. The electronics sector also relies on wax for the production and safeguarding of components. These applications need materials that perform flawlessly consistently, and contemporary wax provides that dependability.

The Science Behind the Performance

Contemporary wax technology thrives because it is founded on robust scientific principles instead of experimentation. Scientists can now create wax molecules with tailored characteristics for specific uses.

This targeted method ensures that companies obtain precisely what they require rather than settling for whatever is at hand. According to the experts at Trecora specialty synthetic waxoffers unmatched performance. Changing molecular structures creates new possibilities. Companies can now specify performance needs and get wax technology to match.

Cost Benefits That Add Up

Many business owners believe that advanced wax technology is more expensive than conventional options. This perspective overlooks the broader scope of overall operational expenses. Contemporary waxes typically outshine and endure longer than traditional substances. They last longer, work better, and cause fewer production problems. These benefits result in actual savings over the long term. Improved performance leads to reduced waste, fewer rejected items, and enhanced quality consistency. Advanced wax is usually a more affordable choice.

Environmental Advantages

Environmental concerns influence many business decisions today. Contemporary wax technology provides multiple benefits in this field. Certain advanced waxes operate effectively at lower temperatures, decreasing energy usage. Some others endure for a longer period, reducing how often replacement and disposal are needed. These ecological advantages frequently correspond with financial savings, resulting in mutually beneficial scenarios for companies.

Making Smart Wax Decisions

Selecting the appropriate wax technology necessitates grasping your unique requirements. The best choice depends on temperature, chemical compatibility, application, and performance. Collaborating with experienced suppliers assists companies in managing the various choices accessible. The wax suitable for one use may be entirely unsuitable for a different application, even within the same field.

Conclusion

Contemporary wax technology offers a substantial chance for companies ready to transcend conventional mindsets. The resources today provide performance, dependability, and affordability that can enhance operations in various sectors. Intelligent companies understand that wax technology has evolved beyond mere coating and protection. It’s focused on precision manufacturing, expense reduction, and strategic edge. Firms that adopt these innovative materials set themselves up for triumph in a progressively challenging market.